What is a Landfill?

Let’s be honest. When most people hear “Landfill” they think “Dump.” You know, that towering pile of random garbage as far as the eye can see? It’s smelly and gross and maybe even dangerous! Well, that was true for some landfills of yesteryear. But that is not at all a true picture of your Regional Landfill. Back in the late 1980s and early 1990s state and federal regulations were put into place to protect the health of both the environment and the community. SPSA is proud to meet and exceed all of those regulations. It’s not just the law – it’s the right thing to do. Modern, secure, and fully contained, the Regional Landfill has been engineered for the highest levels of efficiency and safety.

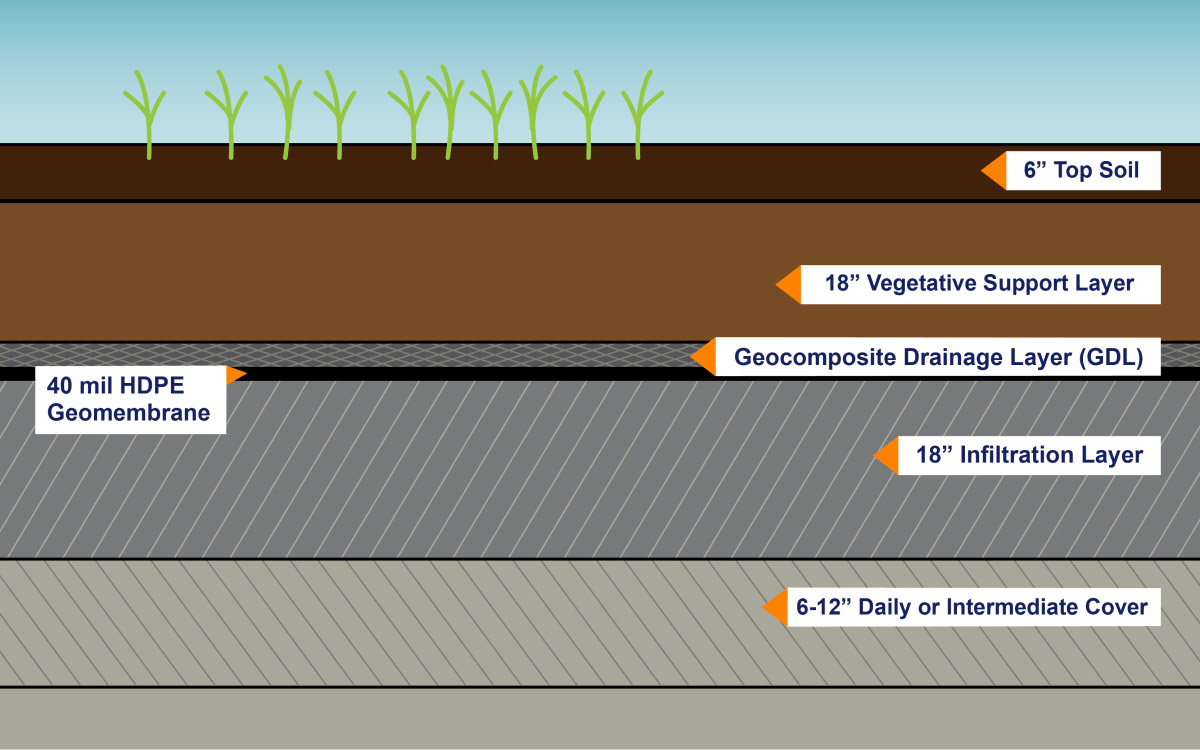

Take a look at the schematic below to see an example of a typical landfill design and learn how it all comes together to take care of your community’s solid waste needs.

WHAT MATERIALS ARE ACCEPTED AT THE LANDFILL?

- Agricultural Waste

- Ash

- Commercial Business Waste

- Construction and Demolition Debris

- Residential Municipal Solid Waste

- Household Garbage

- Institutional Waste

- Industrial Wastes

- Municipal Wastewater Sludge

- Brush and Yard Waste

- SPSA Regional Landfill also separately collects scrap tires and metal for recycling and household hazardous water materials (stains, batteries, oils) for safe disposal.

TYPICAL LANDFILL SCHEMATIC

How the Regional Landfill Works

All along the base of the landfill is a composite liner. Check out the image below for all of the high-tech details, but long story short, it’s specially designed to make sure that the ground (and groundwater) underneath is fully protected from contamination. Also in the base is a “leachate collection system.” As anyone who has ever waited too long to take out their kitchen garbage can tell you, decomposing trash creates liquid. This liquid is called “leachate” and it is collected through a complex series of pipes and pumps (again, see below for the science). The leachate is filtered on site, and then sent to the Hampton Roads Sanitation District’s wastewater treatment system to be turned into clean water.

Solid waste that makes its way into the landfill is first heavily compacted to break it up so it takes up as little room as possible. “Airspace” is a concern at the landfill so we want to condense things as much as the latest technology will allow. At the end of each work day, a 6-inch layer of cover materials is spread over the newly deposited waste to keep down odors and discourage any curious animals from digging. Every 14 days, workers place a 12-inch layer of soil over the working face of the landfill to serve as an Intermediate cover. This cycle continues until the final elevation of the landfill is reached.

Did you know that in addition to liquid, decomposing waste also releases methane gas? Let’s hope that’s not something you have experienced in your kitchen! As layers of waste and cover build up in the landfill, gas collection wells are installed so all that gas can be safely removed. At SPSA, we team with Suffolk Energy Partners to turn that gas into energy to be used locally. It’s a win-win operation that you can learn more about on our Waste-to- Energy page.

Once an area, or “cell” of landfill is full, a final cover system is installed complete with stormwater management plans. (Take a look at the below graphic to see how intricate that process is.) By taking these careful measures, all of the landfill contents stay securely inside and the land continues to serve a useful purpose by supporting vegetation and becoming a habitat for wildlife, like the many wild turkeys that live at the Regional Landfill. The possibilities for that reclaimed land are endless. Some places install solar panels. Others create bike and walking trails. But in the end, the land is there to serve the community’s needs. Just like it has been doing all along.

This video by Practical Engineering does a tremendous job highlighting the creativity and engineering behind landfill design.

BASE LINER

The base liner system at the SPSA Regional Landfill includes a geologic layer, drainage geocomposite (flat pipe) and a 40 mil (40/1000 inch) high density polyethylene (HDPE) geomembrane to collect groundwater during initial operations until enough waste is placed to ballast the groundwater pressure of the inward gradient design. Above the groundwater collection zone is a composite liner consisting of a geosynthetic clay liner, 60 mil (HDPE) geomembrane, leachate collection geocomposite and 18" of protective soil cover materiial. The combination of the geomembrane and geosynthetic clay liner effectively preclude any leakage from the landfill.

Leachate Management System

The leachate management system is comprised of a collection system, submersible pumps, forcemains, leachate pretreatment facility and a pump station and loadout facility to discharge leachate to the wastewater treatment system operated by the Hampton Roads Sanitation District. The collection system includes a geocomposite drainage layer, perforated HDPE piping, stone aggregate and non-woven geotextile filter. After percolating through the waste materials, leachate is transmitted through the protective cover soil into the drainage geocomposite above the 60 mil HDPE geomembrane liner. The geocomposite is comprised of two layers of non-woven geotextile fabric and a drainage net that resembles a lattice. Leachate flows within the geonet layer and is collected by the perforated piping and stone, where it is rapidly directed to the leachate collection sumps. The leachate sump (low spot in each cell or phase) is constructed with a large diameter perforated pipe and stone materials to temporarily store the leachate. A submersible pump is installed within the perforated pipe that uses a pressure transducer and pump control panel to operate the pump to remove the temporarily stored leachate. The pump operates in a manner to maintain compliance with no more than 12-inches of leachate on the base liner system. All of the leachate pump control panels are controlled and monitored through a state of the art Supervisory Control and Data Acquisition (SCADA) system.

Final Cover System

The final cover system at the SPSA Regional Landfill includes an 18" soil infiltration layer over the landfill waste intermediate soil cover, a 40 mil HDPE geomembrane, a drainage geocomposite drainage layer, 18-inches of vegetative support layer and 6-inches of topsoil materials to support the grass vegetation. Slopes of the final cover system are constructed at a maximum of 3 feet horizontal for every vertical foot (3:1) to promote stormwater run-off. Stormwater is managed with drainage benches every 40 vertical feet to reduce erosion potential and to direct run-off to the perimeter drainage ditches and the stormwater managment system. Water that infiltrates to the drainage geocomposite is transmitted down the slopes and is processed into the drainage bench for management with the stormwater.

2-Hour Delay - ALL FACILITIES

2-Hour Delay - ALL FACILITIES